Workwear hoodies are designed to provide warmth and protection in harsh working conditions. Let’s bring your ideas to life with custom designs and high-end fabrics at Thygesen.

Workwear Hoodie Manufacturing Process

Workwear hoodies are designed to provide warmth and protection in harsh working conditions. They are made with heavy-duty materials that are durable and able to withstand frequent wear and tear. The manufacturing process of workwear hoodies involves several stages, including design, pattern making, fabric sourcing, cutting, sewing, and finishing.

Design is the first stage in the Workwear Hoodie Manufacturing process. Workwear hoodies are designed with the specific needs of the end-user in mind. This includes the type of work they will be doing, the environment in which they will be working, and the level of protection they require. Designers take these factors into consideration when creating the hoodie, including features such as reinforced seams, high-quality zippers, and extra pockets for storage.

Once the design is complete, a pattern is created. This pattern is a template that will be used to create the hoodie. It is made by combining the design with the correct measurements to ensure that the hoodie will fit the end-user correctly. The pattern is then used to create a sample hoodie, which is tested to ensure that it meets the design specifications.

When pattern is approved, the next stage of Workwear Hoodie Manufacturing is fabric sourcing. Workwear hoodies are usually made from heavy-duty materials such as cotton, polyester, or a blend of the two. The fabric is sourced from reputable suppliers who are chosen based on the quality of their products and their ability to meet the required delivery schedule. The fabric is then cut into pieces that are required to create the hoodie.

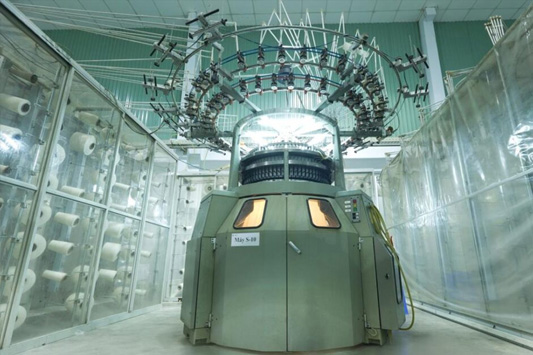

The cutting stage involves using the pattern to cut the fabric into the required pieces. This is done using specialized cutting machines, which are designed to accurately cut the fabric to the correct size and shape. Once the fabric is cut, it is passed on to the sewing stage, where the pieces are sewn together to create the hoodie.

The sewing stage involves joining the pieces of the hoodie together using industrial sewing machines. The machines are operated by skilled seamstresses, who are trained to sew the pieces together to create a high-quality product. The hoodie is sewn together in sections, starting with the sleeves and moving on to the body of the hoodie. Once the hoodie is sewn together, it is passed on to the finishing stage.

The finishing stage involves adding any final touches to the hoodie, such as labels, zippers, or buttons. This stage is important, as it ensures that the hoodie is ready for use. The hoodie is then inspected to ensure that it meets the design specifications and that there are no defects.

In conclusion, the Workwear Hoodie Manufacturing is a complex process that involves several stages, including design, pattern making, fabric sourcing, cutting, sewing, and finishing. The process is carried out by skilled professionals who are trained to produce high-quality hoodies that meet the needs of the end-user. Workwear hoodies are a vital piece of protective clothing that are used in many different industries, and their quality is of utmost importance in ensuring the safety and comfort of the end-user.

Custom Workwear Hoodie Manufacturer

Thygesen Textile Vietnam

Our hoodie collection comes in various styles. Let’s bring your ideas to life with custom designs and high-end fabrics.

Our thoughtful choices of materials and designs help manage the ideal body temperature and moisture level for wearers and make them comfortable all day.

What we offer

✓ Innovative OEM/ODM solutions

✓ High-technology products

✓ Ethical & sustainable manufacturing process

✓ Professional & Supportive team

✓ Competitive price & Timely delivery

Material range and functionality

– CVC, TC, Cotton, Polyester and blended with spandex,…

– Durable, Lightweight, Ease of Movement

– Absorbent, Soft, Comfortable

– All Sizes, Colors, And Customizations Are Available

Quality is our priority

With over 90 years of experience in the textile industry, we are proud to be one of Vietnam’s leading custom workwear manufacturers.

Thygesen has consistently focused on high-quality products and ethical manufacturing processes. With this direction, we can comply with the industry’s most demanding standards while maintaining profitability and motivation.

We are specialized in developing innovative textile solutions for fashion brands, from knitting to ready-made garments.

As a high-quality workwear hoodie manufacturer, Thygesen could help you manufacture any style of workwear hoodie, from plain, printed, designer, and long sleeve t-shirts to longline and oversized styles. Our skillful employees and high-technology machine system allow us to manage the entire process for your brand.

Every stage of the workwear hoodie manufacturing process will be assisted by our experts. We work with you to conceive, design, and envision your finished product. We have our own fabric development system, good contact with reliable printing factories, and strict quality management.

We are focus on CSR

From the beginning, Thygesen Textile Vietnam’s ambition has been to operate ethically and sustainably. Therefore, Corporate Social Responsibility (CSR) is an integrated part of our core business.

Thygesen Textile Vietnam has a long-standing commitment to sustainability and the environment. We recognize that our operations have an impact on the environment and it works to minimize its carbon footprint by using eco-friendly materials and processes. For example, we have invested in state-of-the-art facilities that use renewable energy sources and has implemented recycling programs to reduce waste. Additionallywe use sustainable materials in its products such as organic cotton, to reduce its impact on the environment.

In addition to its environmental efforts, Thygesen Textile Vietnam is also committed to social responsibility. The company has a strong commitment to its employees and provides a safe and healthy working environment. This includes offering competitive wages and benefits, and investing in training and development programs to help its employees grow and succeed. Thygesen also has a strong commitment to its local community and regularly participates in community outreach programs, such as donations to schools and healthcare facilities.

Premium OEM service

OEM (Original Equipment Manufacturer) service refers to a business model where a company provides its manufacturing services to another company to produce products that will be sold under the latter’s brand name. Thygesen Textile Vietnam is a reputable textile manufacturer that offers OEM services to customers.

Thygesen Textile Vietnam has been providing OEM services for over a decade and has established a strong reputation in the industry. With a team of experienced professionals and state-of-the-art facilities, the company has been able to produce high-quality textiles that meet the exact specifications of its clients.

One of the key benefits of working with Thygesen Textile Vietnam for OEM services is that we can provide its clients with a complete end-to-end solution. This includes everything from product design and development to manufacturing, packaging, and shipping. This saves clients time and resources as they do not have to manage multiple vendors or handle different stages of the production process themselves.

Another important benefit of working with Thygesen Textile Vietnam is the company’s commitment to quality. We have a rigorous quality control process in place to ensure that every product produced meets the highest standards. This includes regular inspections throughout the production process to ensure that all products meet the specifications set by the client. This attention to detail results in consistent quality and helps to minimize defects and returns, which can be costly for businesses.

Thygesen Textile Vietnam’s CSR efforts are not just limited to its operations. The company also works with its suppliers and customers to promote sustainable practices and raise awareness about the importance of sustainability. This includes collaborating with suppliers to reduce their carbon footprint and promoting eco-friendly practices among its customers through education and outreach programs.

Another important aspect of Thygesen Textile Vietnam’s CSR efforts is its commitment to transparency and accountability. The company regularly publishes reports on its sustainability efforts and makes its operations and practices available for public scrutiny. This openness and transparency helps to build trust with stakeholders and demonstrates the company’s commitment to making a positive impact on the world.

Thygesen’s Workwear Hoodie Products

Workwear Cotton Hoodie

With over 90 years of experience in custom workwear manufacturing, you can rely on our knowledge and expertise. We can manage every aspect of your products, from concept development and sampling to manufacturing and logistics. We are confident to bring you the best service.

Reflective Hoodie

Reflective workwear hoodies help the wearer feel comfortable to move but also ensure visibility and safety at work. Our range of reflective hoodies comes in various colors including those that have been proven to be more visible at night or during weather with reduced visibility.

Workwear Wool Hoodie

Wool hoodie is incredibly comfortable for the whole working day, as wool fabric is a remarkably elastic material. If you’re looking for a manufacturer who can assist you produce workwear/uniform products with full support, Thygesen Textile Vietnam would be a great option.

Workwear Basic Hoodie

A perfect hoodie for winter working day made and supplied by Thygesen’s One-Stop-Shop service. It’s destined to provide customers a supportive manufacturing solution to cut more cost, save more time and satisfy customer with better quality product.