Manufacturers must use a warehouse to connect the supply chain and production activities in the garment industry. It is much more than a place to store ordinary goods. Manufacturers will use the warehouse as an intermediary to link their production activities with the supply chain from importing raw materials to exporting finished products to customers. The importance and guidelines related to warehouse in garment industry will be shared in this article. Read on for more useful information!

What is warehouse in garment industry?

Warehouse in garment industry is not only a commercial building to store garment-related items, but also equipped with many machines and management systems to connect with other supply chains. Every garment manufacturer must have its own effective warehouse system to ensure the supply chain operates continuously.

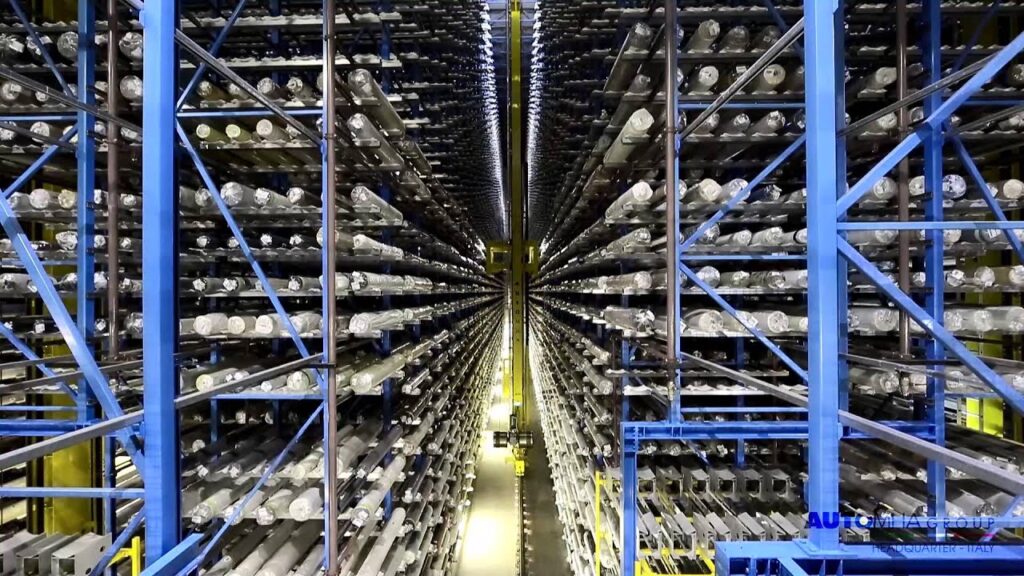

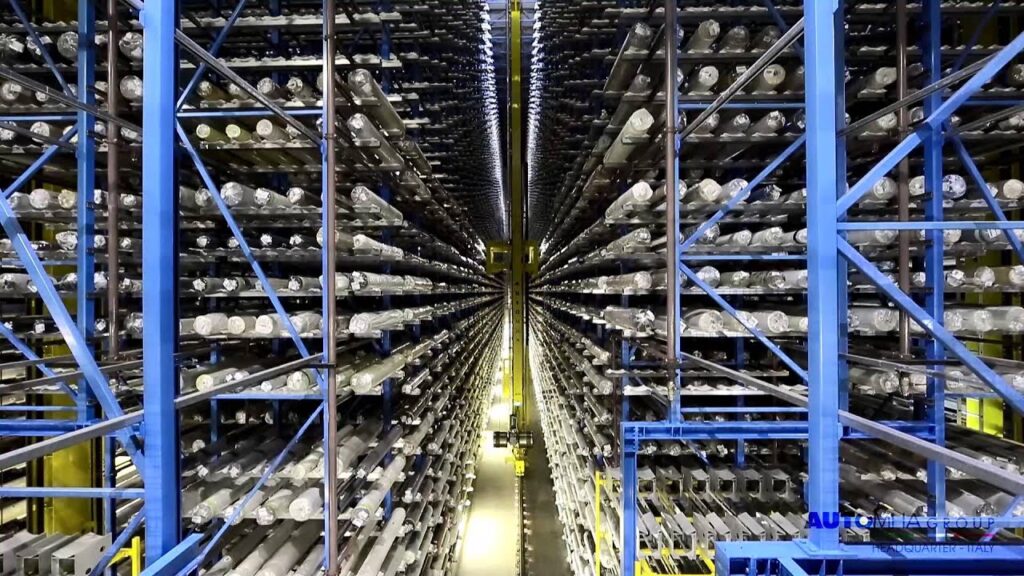

The warehouse where the raw materials will be stored for the initial production of apparel for garment factories. It can also house finished or packaged garments in preparation for shipment to the buyer. There are many types of warehouses and they have their own warehouse management system to ensure the quality and information of the costumes and materials. However, modern technology develops as today has turned warehouses into automation. Large warehouses are often managed by robots and modern machines. The garment warehouse manager only needs to organize and redefine the accuracy of the paperwork.

Importance of warehouse in textile industry

Warehouse in garment industry has many important roles. You can track some of the roles through the shares below:

Control of raw materials and garments

The smart management system of the warehouses will help garment manufacturers control imported materials, materials used for production, finished products in stock, products delivered to customers and much more. It helps manufacturers know the status of raw materials needed for the production process such as sufficient, missing or lost as well as the status of goods in stock to make appropriate production decisions.

Ensure a continuous supply chain

Garment manufacturers often tend to mass produce some items to deliver to the market faster when there is demand. Warehouse in garment industry help them maintain an efficient supply chain as they have storage space for materials from their suppliers and this is where the goods are shipped to their customers. The delivery process will take place faster to save maximum time.

Better garment protection

Finished garment products need to be protected in appropriate conditions to ensure quality before being delivered to customers. Creating a professional home environment will help manufacturers protect bulk goods effectively.

Inventory control

For garment manufacturers, controlling the actual amount of inventory will help them avoid unnecessary losses. Building a modern warehouse in garment industry will help them inventory more efficiently. Everything is strictly controlled through management software on the computer to be able to grasp the situation and settle inventory in time, avoiding capital loss.

Warehouse management system in Apparel

The warehouse management system is the system that manages the entire operation of the garment warehouse. Previously, warehouse management was done manually with paperwork and human work, but now it is modernized by technology and software. Modern management technologies are integrated into the machines so that warehouse staff can enter or update data about delivery information, dispatch information and more. The warehouse management system will also manage incoming and outgoing materials for production, finished garments, delivered garments and more.

If you want to know more about warehouse management system in apparel then you can learn below:

Materials received

All information regarding material orders will be collected including invoices and material inspection reports. Before checking the goods to enter the warehouse, the goods will be verified through the invoice and the container lock. After that, the material will, according to the pre-ordered quantity counted and verified, re-entered into the warehouse.

Raw materials inventory

Materials in stock will be verified by quantity or weight with complete retention information such as purchaser/color/lot/style/batch/size within 48 hours of receipt. If any problems are found during the inspection, the seller or supplier will be notified. Discussions will take place to find the most suitable option. The database software will best support the storage of inventory.

Software versus physical inventory management

Although the use of management software is more convenient than manual and physical management, the current warehouse in garment industry combines both management methods. Physical inventory checks will be conducted on a weekly or monthly basis. It helps employees to have accurate information about the amount of goods in the warehouse. If there is any deviation from reality, everything will be compared and adjusted accordingly.

Material storage system

After completing the inventory process, the goods will be kept in an isolated area for inspection and testing. Through the inspection steps, the material will be accepted and distributed to the appropriate storage areas. Location tables and registrations will be established and maintained for easier traceability of goods.

Materials and goods will be carefully stored on racks/pallets to ensure quality. Warehouses must always be clean, dry, away from sunlight and moderate humidity.

Material storage refusal system

Damaged materials or goods will be stored in a designated disposal area. The defect test reports will be archived and shared with the supplier. Defective materials can be returned or kept for up to 6 months in the quarantine area. After that, it can be decided to destroy or take other measures.

Inventory policy

Inventory products must be kept for a minimum of 6 months in the quarantine area before they can receive management decisions from other policies. As inventory, they can be de-labelled and locked to protect the customer’s brand.

5S in warehouse management

Building a warehouse in garment industry is really not easy. To create perfect warehouses, we need to have the right management. 5S in warehouse management is one of the effective warehouse operation solutions.

What is 5S?

5S standards are widely used in many business and management activities

5S is a lean strategy that helps you have a neat and organized warehouse. In simple terms, 5S warehouse arrangement is a method, an implementation step of “Lean” (Lean Manufacturing) to achieve a single purpose that is to simplify the working process.

5S standards are widely used in many business and management activities. In particular, applying 5S standards in inventory management helps you optimize order time and perfect the warehouse management model for retail shops, factories and businesses.

The 5S standard originates from the Japanese automaker Toyota and is abbreviated by 5 words: Seri (SORT), Seiton (SET IN ORDER), Seiso (STANDARDIZE), Seiketsu (SUSTAINT) and Shitsuke (SELF-DISCIPLINE).

- Series (SORT): Sort, remove unnecessary things, can be sold or reused.

- Seiton (SET IN ORDER): Conduct a scientific and reasonable arrangement of products according to the criteria of easy to find, easy to see, easy to get, easy to return.

- Seiso (STANDARDIZE): The warehouse space is regularly cleaned and organized with items that are regularly maintained and neatly arranged.

- Seiketsu (SUSTAINT): Always check, maintain the 3S standard above.

- Shitsuke (SELF-DISCIPLINE): Train, create a habit, order, and style for everyone in the enterprise to implement 5S.

Benefits of 5S

In order to identify anomalies, help all problems be clearly seen, 5S can eliminate the maximum waste of time and effort, organize and manage the entire work system. This standard also provides an ideal and optimal working environment, thereby ensuring the highest level of work performance at all times. This inventory management method actually brings more benefits than we think. Here are some typical benefits you can refer to.

- Strictly manage the warehouse, avoid maximum loss of goods

- Be more active in business, balance in import and export

- Increase labor productivity, cut logistics costs

- Clean and professional working environment. Improve the working style of the staff

Conclusion

Warehouse in garment industry plays an important role when helping garment manufacturers save costs in warehouse management, goods preservation and maintaining a continuous supply chain. In addition, the inventory management system in apparel becomes more modern, which also helps people save a lot of effort. One of the management methods applied by many businesses is 5S. Hopefully, the information we share in this article can help you build and manage a garment warehouse more effectively!